T. Sobisch, D. Lerche, S. Küchler, A. Uhl,

L.U.M. GmbH, Rudower Chaussee 29 (OWZ), 12489 D-Berlin, Germany,

Paper Proceedings Euro Food Chem XIII, Macromolecules and their degradation products in food – physiological, analytical and technological aspects,

Keywords

Analytical centrifugation; Dispersions; Emulsions; Separation Stability; Destabilization Kinetics

SUMMARY

A new multisample approach is presented using analytical centrifugation, which allows for an accelerated characterization of destabilization processes (creaming, sedimentation, coalescence, phase separation). The kinetics of these destabilizing processes can be traced simultaneously for up-to 12 different samples with temperature control down to 4 °C. Analytical centrifugation measures the inherent stability of the samples, but cannot foresee destabilizing processes which will happen in the future. In this respect a combination with common accelerated stability testing is the method of choice. The wide application potential of this approach is demonstrated by examples of measurements on typical food dispersions like beverages, emulsions, milk and milk based products.

INTRODUCTION

A considerable fraction of food products are dispersions (emulsions, suspensions, suspoemulsions). Therefore, not only the microbiological and chemical stability matters, but the separation stability has also to be characterized. The development of new food formulations as well as process development/monitoring and quality assurance require efficient and objective analytical tools for shelf life prediction and stability determination. To this end the potential of multisample analytical centrifugation was evaluated as an accelerated test procedure.

EXPERIMENTAL

Methods

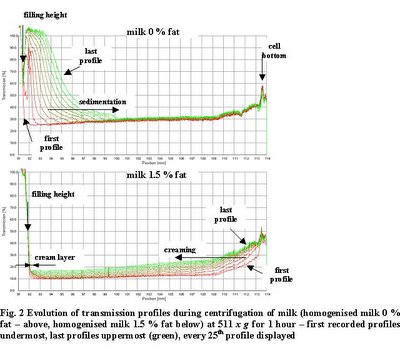

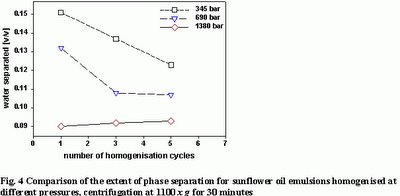

The multisample analytical centrifuge - LUMiFuge® (L.U.M. GmbH Germany) used in this study employs the STEP technology, which allows to measure the intensity of the transmitted light as function of time and position over the entire sample length simultaneously (Measurement scheme see Fig. 1).

The data are displayed as function of the radial position, as distance from the centre of the rotation (transmission profiles, see Fig. 2). The progression of the transmission profiles contains the information on the kinetics of the destabilization processes (creaming, sedimentation, coalescence, phase separation) [1-2]. At the same time up to 12 different samples can be analysed at constant or variable centrifugal speed up to 2300 x g. The separation behaviour of the individual samples can be compared and analysed in detail by tracing the variation in transmission at any part of the sample or by tracing the movement of any phase boundary.

Sample pretreatment

RESULTS AND DISCUSSION

Comparison of the separation stability for different formulations is a frequent task. As an example the creaming behaviour of cream liqueur samples of different composition is compared (Fig. 3). The creaming kinetics can be analysed by tracing the movement of the phase boundary cream – separated continuous phase (sugar solution). The position of this boundary is denoted as distance from the centre of rotation.

The initial creaming rate is given by the slope at the start of centrifugation, the equilibrium height of the separated continuous phase as difference between the position of the cell bottom (113.8 mm) and the position of the phase boundary at equilibrium. Experiments were repeated at several other centrifugal accelerations to check whether the order of stability depends on this parameter (Tab.1). As the order of stability is (3) > (1) > (2) independent of the centrifugal acceleration results should be valid at normal gravity too.

Table 1. Initial creaming velocity for cream liqueur samples 1 to 3, determined for centrifugation at 128, 287 and 1100 x g

| sample | velocity at 128 x g [µm/s] | velocity at 287 x g [µm/s] | velocity at 1100 x g [µm/s] |

| (1) | 2,0 | 4,2 | 15,5 |

| (2) | 3,5 | 7,4 | 33,0 |

| (3) | 1,1 | 2,2 | 9,9 |

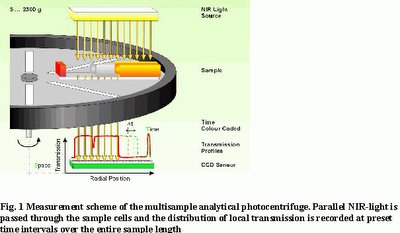

Selection of processing conditions for the manufacturing process is a key for economic production of stable products. Fig. 4 gives an example for the preparation of sunflower oil emulsions with the Microfluidizer® technology varying the homogenisation pressure and number of processing cycles. As obvious from Fig. 4 homogenisation efficiency is highest at the highest pressure, repeated homogenisation is only useful at lower homogenisation pressures.

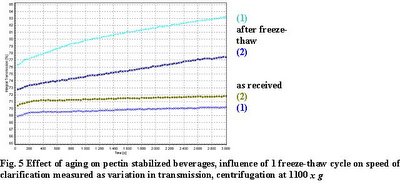

Evaluation of long term stability is often complicated by slow diffusion based destabilization processes, which cannot be foreseen by analytical centrifugation. However, the result of these processes can be traced far more faster then by naked eye. An example is given in Fig. 5 for pectin stabilized beverage samples. In this case the stability was measured by the variation of turbidity during centrifugation. As can be seen the fresh samples exhibited a similar behaviour. However, they were markedly destabilized after only one freeze-thaw cycle. After this, sample (1) showed a substantial higher loss of stability. The same trends were observed after 6 week of storage but less pronounced.

Acknowledgement

We thank for the support of the Bundesministerium für Wirtschaft und Technologie (grant number KA 0047301AWZ3).

REFERENCES

[1] T. Sobisch, D. Lerche, SCI/RSC/SCS Conference Cosmetics and Colloids, London 15 February 2005

http://www.soci.org/SCI/groups/col/2005/reports/pdf/gs3257_sob.pdf

[2] T. Sobisch, D. Lerche, Chemistry Preprint Archive, Volume 2004, Issue 5, May 2004, Pages 7-18

No comments:

Post a Comment